GET A QUOTE

OVERVIEW

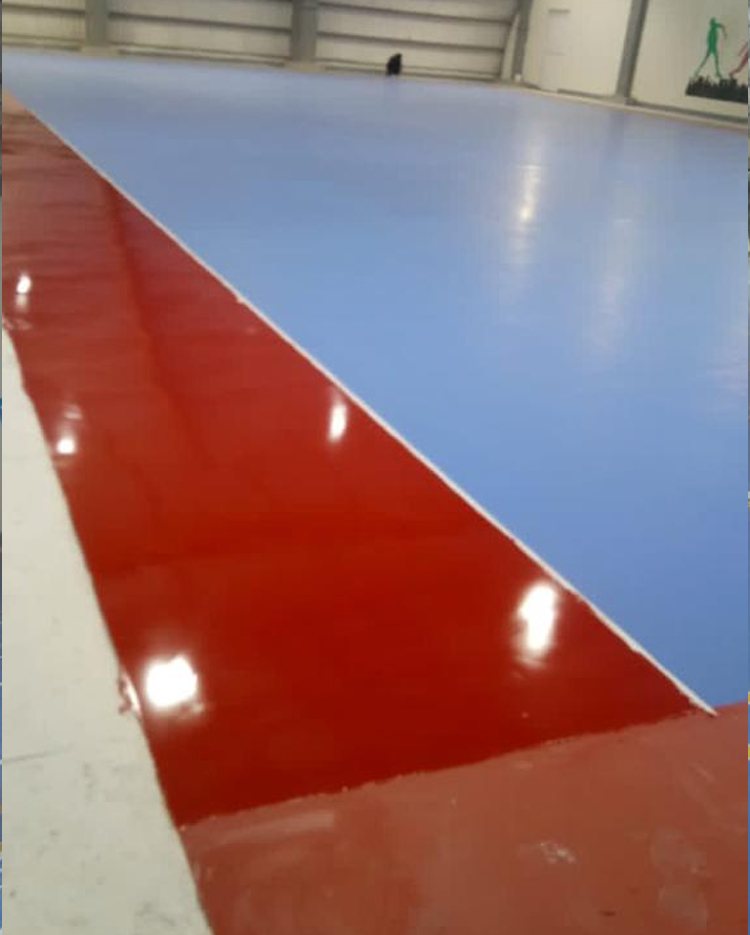

Epoxy Flooring

Universal Services are well-known providers of epoxy flooring and 3D epoxy services all over Karachi Lahore and Islamabad for industrial, commercial and also residential purposes. Epoxy coating is mostly done on concrete floors to provide a sturdy and durable surface that can withstand heavy loads. Epoxy coating also creates shiny glossy and a seamless surface which makes the interior a sight to wonder and an everlasting surface. That is why many industries in Pakistan rely on epoxy flooring to provide a safe and comfortable working environment for the workers and manage inventories and equipment conveniently.

FEATURED

Epoxy Coating & Flooring Services In Karachi Islamabad & Lahore

Universal services are one of the most reliable names when it comes to affordable waterproofing services in Pakistan. Your search to fix your wet basement and roof is now over since you are the right place to get all your waterproofing done at the lowest prices. We are the oldest waterproofing contractors offering services in Karachi, Lahore, Islamabad, Multan, and all other major cities of Pakistan. We have an expert team having years of experience damp basements, water crawls, and all types of waterproofing work in Karachi, Lahore, and Islamabad at best prices. As a trustworthy waterproofing company in Pakistan, we use top quality waterproofing membrane and finest quality chemicals to ensure the best and long-lasting results.

Dedicated Team

True Partners

Global Know-How

Focus On Innovation

GET A QUOTE

RELATED PROJECT

Projects in the field

Residential Home DHA Phase 5

Work Type: Bitumen coating

Approximate area: 2200Sqft

Location: Indus hospital korangi

View details

Q Mobile Head Office

Work Type: Bitumen coating

Approximate area: 2200Sqft

Location: Indus hospital korangi

View details

Khayban Baghban DHA

Work Type: Bitumen coating

Approximate area: 2200Sqft

Location: Indus hospital korangi

View details

Kahyban Bahria DHA

Work Type: Bitumen coating

Approximate area: 2200Sqft

Location: Indus hospital korangi

View details

Bhit Shah Auditorium

Work Type: Bitumen coating

Approximate area: 2200Sqft

Location: Indus hospital korangi

View details

ASF Bitumen Coating

Work Type: Bitumen coating

Approximate area: 2200Sqft

Location: Indus hospital korangi

View details

J. Factory Unit No. 5

Work Type: Heat Proofing

Approximate area: 4200Sqft

Location: Hussain Towel, Zurash Industry, Korangi

View details

Peshawar Development Authority

Work Type: Heat Proofing

Approximate area: 2800Sqft

Location: Beacon House School

View details

Khayban e Baghban DHA Karachi

Work Type: Heat Proofing

Approximate area: 4200Sqft

Location: Hussain Towel, Zurash Industry, Korangi

View details

NUST University Islamabad

Work Type: PU Epoxy Coating

Location: NUST University Islamabad

View details

Chase Value Center

Work Type: Heat Proofing

Approximate area: 13500Sqft

Location: Chase Value Center Rashid Minhas Road

View details

Beacon House School System

Work Type: Heat Proofing

Approximate area: 2800Sqft

Location: Beacon House School

View details

Khayban Ameer Khusro

Work Type: Heat & Waterproofing

Approximate area: 4000Sqft

Location: Khayaban Ameer Khusro DHA Phase 6 Karachi

View details

SNBS Johar

Work Type: Heat Proofing

Approximate area: 4200Sqft

Location: Hussain Towel, Zurash Industry, Korangi

View details

Fair Textile Mills

Work Type: Heat Proofing

Approximate area: 4200Sqft

Location: Hussain Towel, Zurash Industry, Korangi

View details

Hussain Towel

Work Type: Heat Proofing

Approximate area: 4200Sqft

Location: Hussain Towel, Zurash Industry, Korangi

View details

Indus Hospital Korangi

Work Type: Bitumen coating

Approximate area: 2200Sqft

Location: Indus hospital korangi

View details

Residential Work

Work Type: Heat Proofing

Approximate area: 1800Sqft

Location: Khayaban e Bukhari, DHA Phase 6, Karachi

View details